Product Line

Home > Product Line > Chemical & Plastic Dep. > Dosing & Feeder

Dosing & Feeder

MC-Balance MC-Twin MC-High Output MC-Multi-Component

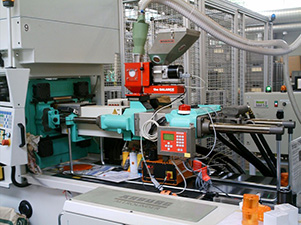

MCBalance test unit

Maximum gravimetric dosing control for injection molding and extrusion

Overview

Gravimetric in-line dosing system MCBalance offers plastic producing companies maximum control, maximum efficiency and maximum savings. Through continuous loss-in-weight measuring, one is ensured of the best results for the best price. The MCBalance dosing system continuously calibrates the dosages and adjusts automatically. The MCLan enables the producer to monitor all MCBalance dosing systems from one computer. Plastic processors worldwide choose this gravimetric dosing unit for stability in coloring with masterbatch, powder or regrind. This gravimetric unit can easily be adjusted to a multi-component system, so that you can dose up to six additives at the same time.

FEATURES- Continues loss-in-weight measuring

- Automatic material calibration

- Integrated hopper loader control

- Warning and alarm output

- Recipes storage function

- Communication TCP/IP, Modbus and Profibus

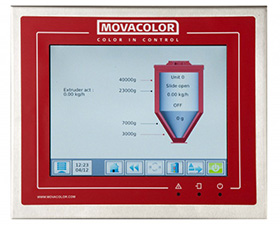

- Menu guided control and graphic, LCD display with backlight, or 8 inch full color touch screen for simple operation of single and multi-component systems

- Control for extrusion: % setpoint adjustment, auto synchronization to extruder speed

- Control for injection molding: % setpoint adjustment, auto metering time synchronization

- Capacity 0,07-180 kg/h, measured with normal granular masterbatch 0,8 kg/dm3

Benefits - Return on investment less than a year (six to nine months is not unusual)

- Saving on additives up to 50%

- Stability guaranteed

- Less color variation

- No stoppages or pulsing with the stepper motor

- Steady flow with the dosing cylinder dosing directly in the main material

- Easy to operate and easy to clean

- Color changes can be realized within 30 seconds

- Lots of possibilities to adjust or upgrade the dosing unit

Download

MC-Balance Brochure

MC-Balance Brochure

MCTwin

Dosing regrind and masterbatch simultaneously with the MCTwin

Overview

Setting the goal for saving colorants ánd efficiently re-using rejects and sprouts? The MCTwin is the name of the dosing unit you are looking for. This dosing system offers gravimetric control over the injection molding production process.

The MCTwin is a gravimetric dosage system that combines two MCBalance dosing units. The MCBalance features proven technology that contributes to stability, efficiency, savings and quality. One dosing unit functions as the master unit. This dosing system doses the regrind. The second dosing unit follows the master unit. In practice this means that the regrind is used optimally and the masterbatch is added when necessary for sufficient colorant. This enables plastics producers to prevent the overconsumption of masterbatch.FEATURES

- Continues loss-in-weight measuring

- Automatic material calibration

- Integrated hopper loader control

- Warning and alarm output

- Recipes storage function

- Communication TCP/IP, Modbus and Profibus

- Menu guided control and graphic, LCD display with backlight, or 8 inch full color touch screen

- Control for injection molding: % setpoint adjustment, auto metering time synchronization

- Capacity 0,07-180 kg/h, measured with normal granular masterbatch 0,8 kg/dm3

Benefits - Efficient use of rejects and sprouts

- Return on investment less than a year (six to nine months is not unusual)

- Stability guaranteed

- Saving on additives up to 50%

- No stoppages or pulsing with the stepper motor

- Less color variation

- Steady flow with the dosing cylinder dosing directly in the main material

- Color changes can be realized within 60 seconds

- Easy to operate and easy to clean

MCHigh Output gravimetric dosing system for dosing up to 1000kg/h

Overview

When it comes to high output dosing, dosing unit MCHigh Output offers the best solution in terms of control, efficiency and savings. Gravimetric in-line dosing system MCHigh Output has two load cells for continuously weighing through loss-in-weight measurement. The dosage system doses additives like masterbatch, regrind and powders from 50 kg/h up to 1000 kg/h. The MCHigh Output can also be used for flakes and hot materials up to 180 °C. The full gravimetric dosage system monitors the output continuously and adjusts automatically. The MCLan enables to monitor all MCHigh Output and MCBalance dosing systems from one computer.

MCHigh Output system for extrusion features:

- Continues loss-in-weight measuring

- Drain and material calibration connection

- Integrated slide valve to control the material loading.

- Integrated hopper loader control

- Warning and alarm output

- Recipes storage function

- Communication TCP/IP, Modbus, Canbus and Profibus

- Menu guided control and graphic, LCD display with backlight, or

- 8 inch full colour touch screen for simple operation of single or multi-components

- Control for extrusion: % setpoint adjustment, auto synchronization to extruder speed

- Capacity from 50 kg/h up to 1000 kg/h depending on the material

Benefits - Accurate dosing of high output masterbatch, powder or regrind up to 1000 kg/h

- Maximum control through controls, dosing cylinder and stepper motor

- Maximum stability in the coloring process

- Maximum savings on colorants

- For operators easy to operate and also easy to clean

- The allowance of quick change of colorants

How is my production process ensured of accurate dosing?

“The MCHigh Output is perfectly capable of dosing our dried PET flakes that reach up to 180 °C”

MC-Multi-Component

Dosing up to five different additives in injection molding and extrusion

Overview

Producers of plastic in injection molding or extrusion who use multiple additives or a mixture of powders and granulates at the same time can opt for a multi-component Movacolor dosing system. One system can dose up to five (different) additives full fed or starve fed on the extruder allowing the producer to optimize the recipe of the extruder feed and eliminating pre-blending requirements.

One of the major advantages of the modular concept of the Movacolor dosing units is that it allows you to combine several (different) type of gravimetric dosing systems. Adjustment or upgrading is easy and you don’t have to buy a complete new dosing unit. Multi-component systems are always customized in that way that it is depending on your production process which combination will work for the best.FEATURES

- Continues loss-in-weight measuring

- Automatic material calibration

- Integrated hopper loader control

- Warning and alarm output

- Recipes storage function

- Communication TCP/IP, Modbus and Profibus, Analog

- 8 inch full color touch screen for simple operation of single and multi-component systems

- Control for extrusion: % setpoint adjustment, auto synchronization to extruder speed

- Control for injection molding: % setpoint adjustment, auto metering time synchronization

- Dosing capacity up to 1000kg/h, measured with normal granular masterbatch 0,8 kg/dm3

Benefits - Dosing multiple additives or a mixture of additives

- Easily adjustment or upgrading

- Stable production process when it comes to coloring the plastic products

- Return on investment less than a year (six to nine months is not unusual)

- Saving on additives up to 50%

- Steady flow with the dosing cylinder dosing directly in the main material

- Easy to operate and easy to clean

- Color changes can be realized within 30 seconds

- Warranty up to 5 years

Download

MC-Multi-Component Brochure

MC-Multi-Component Brochure